How to Drill Axle Holes for Small Wheels Made From Dowel Stock

Learn to accurately find the center of toy wheels cut from dowel stock.

This article takes you step-by-by on creating a jig to help you accurately and quickly drill the center axle hole for toy wheels cut from dowels.

To download a PDF file of this How-To scroll to the bottom of this article.

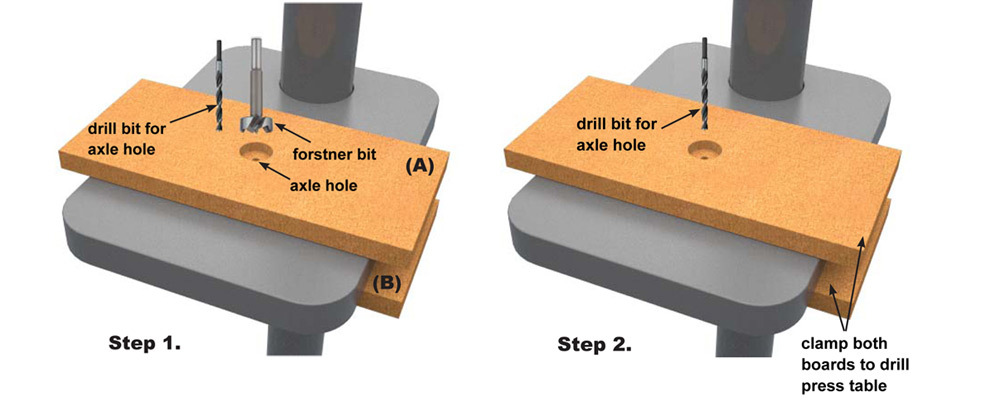

Step 1.

Cut two pieces of lumber 3/4” 5-1/2” x 12”. Medium Density Particle Board works well for production jigs. Use a drill bit the diameter of the wheel axle hole to drill a hole through the center of (A). Next use a Forstner Bit the diameter of the wheel to drill a hole aligned with the axle hole to a depth of 1/2 the thickness of the wheels to be drilled.

Step 2.

Use the undrilled board (B) to assist in clamping (A) to the drill press table while aligning (A) with the axle hole by lowering the axle hole drill bit mounted in the drill press into the hole in (A).

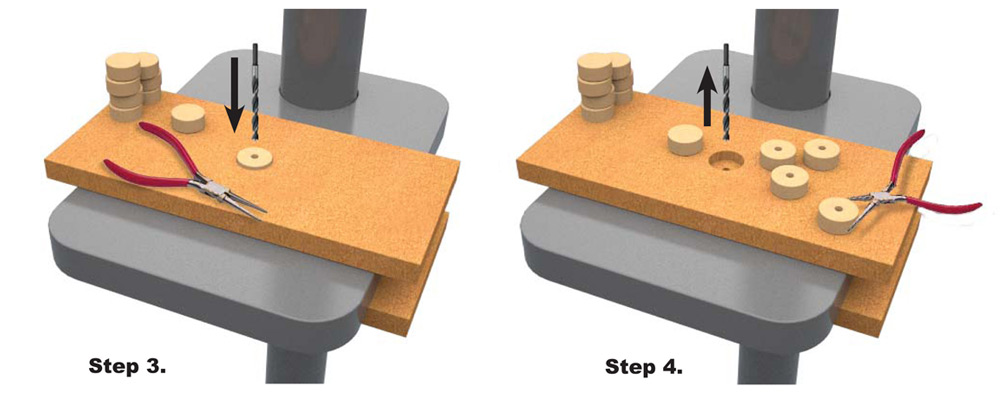

Step 3.

Place an undrilled wheel blank into the wheel cavity in (A) and drill the wheel through using the axle hole bit.

Step 4.

Use a pair of needle nose pliers to grip the wheel while drilling the wheel to keep the wheel from spinning. The pliers are also handy for quickly removing the drilled wheel and then for inserting an undrilled wheel for drilling.