How to Choose the Correct Scroll Saw Blade (page 2)

Blades are measured in TPI or teeth per inch.

More teeth per inch increases the blade’s ability to cut the details required for fine work.

SOME BASIC SCROLL SAW BLADE TYPES:

Available in both pin-ended and plain ended styles.

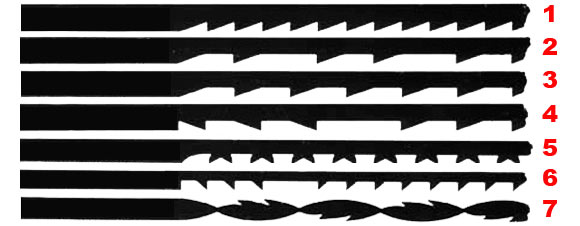

1. Standard Tooth Blades: Available for both wood and metal. Teeth are the same size and distance apart. Wood blades have large teeth and more space between the teeth which easily clear out sawdust when cutting. Standard metal blades have small teeth and less space between teeth.

2. Double-tooth Blades: A double-tooth blade is a skip-tooth blade with a large space between sets of two teeth. This blade require slow cutting but will create a fine smooth cut.

3. Skip-tooth Blades: These blades are the same as standard tooth blades with every other tooth missing. The gullet between teeth is widened to keep the blade cool. Skip-tooth blades are a great blade to use for most toymaking.

4. Reverse Skip-tooth Blades: These blades are the same as regular skip-tooth blades but have a select number of bottom teeth pointing upward. The novel design prevents most splintering on the underside of the cut. This blade is preferred when sawing plywood. If your saw allows it, place the blade so that only two or three teeth are above the table top with the saw arm in the highest position.

5. Crown-tooth Blades: With this innovative design, the teeth are crowned with a space between each crown. The blade can be placed in the saw in either direction. There is no up and down when installing this type of blade. Slower than a regular blade, they are great for cutting plastic or Plexiglas®. As the blade dulls it can be reversed for more sharp sawing.

6. Precision-ground Blades: These blades are actually a skip-tooth blade with small teeth that have been ground to shape rather than simply filed. These blades are much sharper, cut a precision line and leave a very smooth surface. I prefer Precision Ground Tooth (PGT) blades because it’s easier to follow a pattern line.

7. Spiral Blades: These blades are simply a group of blades twisted together so there are teeth all the way around. You can cut in all directions without turning the wood. There are a few applications for this kind of blade, but they leave a very rough, wide cut surface, can’t make a tight or sharp corner and have a tendency to stretch as you use them. I do not recommend these blades except for special applications.

8. Specialty Blades: There are numerous special blades designed to cut metal, plastic and even glass. There are also blade-type scroll saw inserts for sanding and filing that are featured on page 9 of this issue.

Scrolling is a lot easier and much more fun when blades are understood and the right blade is used.

Choosing the right scroll saw blade for the job increases your chances of success and makes scrolling a lot safer. The type of blade that you choose is based on the thickness and hardness of the type of wood you’re using for your project. Materials like Plexiglas and aluminum require a blade made especially for that material. Almost all wood is cut with standard blades.

All types of scroll saw blades are manufactured by stamping from steel blanks which can leave small burrs on the blade. PGT scroll saw blades are stamped, hardened and then finished by grinding. These types of blades stay sharper longer and are less likely to break.

Scrolling is a lot easier and much more fun when blades are understood and the right blade is used.

Choosing the right scroll saw blade for the job increases your chances of success and makes scrolling a lot safer. The type of blade that you choose is based on the thickness and hardness of the type of wood you’re using for your project. Materials like Plexiglas and aluminum require a blade made especially for that material. Almost all wood is cut with standard blades.

All types of scroll saw blades are manufactured by stamping from steel blanks which can leave small burrs on the blade. PGT scroll saw blades are stamped, hardened and then finished by grinding. These types of blades stay sharper longer and are less likely to break.

The highest quality scroll saw blades also use top quality steel and a refined tempering process.

This is important when cutting difficult hardwoods. Hardwoods require a higher number blade, where the blade kerf (width of cut) is larger allowing for easier dust clear out. This type of blade is also useful with oily woods.

The greater blade thickness also results in a longer blade life when used on denser woods. Gummy white pine works best with a skip tooth blade. With more space between the teeth of a skip tooth there’s more efficient dust removal.

When scroll sawing thick wood choose a blade with less teeth per inch. With thin wood choose a blade with more teeth per inch.

A good rule of thumb is to keep at least 4 teeth in the wood at all times on thick wood stock and at least 3 teeth per inch in the wood at all times in thin wood stock.

A scroll saw blade with too many teeth for the job keeps the sawdust from clearing out. The blade soon can get too hot causing the wood to burn. A scroll saw blade with too few teeth will snag the wood. This causes the wood to jump up and down on the table and sometimes become completely out of control.

When scroll sawing delicate fretwork patterns use a high tooth-count blade to maintain better control when sawing. When scroll sawing long gentle curves for outside cuts on a piece of wood, using a blade with less teeth will increase the speed of cutting. The cut will be a little rougher but your sawing speed will increase greatly.